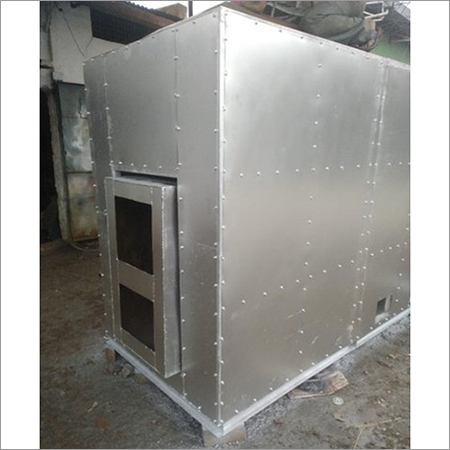

Stress Relieving Furnace

Price 50000-200000 INR/ Unit

Stress Relieving Furnace Specification

- Rating

- Industrial Standard

- Feature

- Uniform Temperature Distribution, High Thermal Efficiency, Programmable Temperature Controller

- Condition

- New

- Type

- Electric/ Gas Fired

- Usage

- Stress Relieving of metal components

- Power

- 15 KW

- Voltage

- 380-440 V

- Size

- Customizable as per requirement

- Dimensions

- 3000 x 1800 x 1800 mm (standard, customizable options available)

- Weight

- Approx. 3500 Kg

- Application

- Stress Relieving Heat Treatment processes for fabricated and welded structures

- Fuel Type

- Electric / Natural Gas

- Capacity

- 2 to 15 Tons (Customizable)

- Loading Type

- Manual / Trolley Loading

- Insulation Thickness

- 180 mm

- Temperature Range

- Up to 950°C

- Safety Features

- Over-temperature protection, Emergency Shutoff

- Surface Finish

- Powder Coated / Painted

- Ambient Operating Temperature

- 5°C to 50°C

- Control System

- Digital PLC-controlled system

- Cooling Method

- Natural / Forced Air

- Door Type

- Horizontal Sliding / Swing Type

- Inner Chamber Material

- Stainless Steel (Heat resistant)

- Heating Element Material

- Kanthal / Silicon Carbide

Stress Relieving Furnace Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 2-3 Week

About Stress Relieving Furnace

Advanced Control and Safety

Equipped with a modern PLC-controlled system, this furnace allows for highly accurate temperature management and process automation. Safety features include over-temperature protection and emergency shutoff, ensuring operator and equipment security during stress relieving operations. The user-friendly control interface ensures convenient programming and monitoring.

Customizable to Your Needs

Manufactured to meet varied industrial requirements, this furnace offers customizable dimensions, loading styles, and capacities. Whether you need manual or trolley loading, or prefer electric or natural gas power, the system is tailored to suit your specific application, providing flexibility and operational adaptability.

Superior Build and Energy Efficiency

With a rugged stainless steel inner chamber, advanced insulation, and Kanthal or Silicon Carbide heating elements, the furnace delivers outstanding durability and energy efficiency. Features like uniform temperature distribution and programmable controllers result in consistent, high-quality heat treatment outcomes.

FAQ's of Stress Relieving Furnace:

Q: How does the digital PLC-controlled system enhance the stress relieving process?

A: The digital PLC-controlled system allows for precise setting, monitoring, and automation of temperature and timing, ensuring the metal components are stress relieved uniformly and consistently. This enhances overall process reliability and product quality.Q: What types of loading options are available, and which is suitable for my application?

A: You can choose between manual and trolley loading depending on your workflow and material size. Manual loading is suitable for smaller components, while trolley loading facilitates handling of larger or heavier items, enhancing operational safety and efficiency.Q: When should I use forced air cooling rather than natural cooling in this furnace?

A: Forced air cooling is recommended when quicker cooling rates are required or when processing heat-sensitive materials. It helps reduce turnaround times and increase throughput, whereas natural cooling is suited for less time-sensitive applications.Q: What safety features are integrated into the furnace to protect operators and equipment?

A: The furnace is equipped with over-temperature protection, an emergency shutdown system, and robust door locking mechanisms to ensure maximum safety. These features prevent overheating, accidental exposure, and potential hazards during operation.Q: Where can this stress relieving furnace be installed and used?

A: This furnace is designed for industrial settings such as fabrication shops, metalworking plants, and manufacturing facilities in India and abroad. Its ambient operating temperature range of 5C to 50C ensures adaptability to various factory environments.Q: What are the primary benefits of using this furnace for stress relieving heat treatment?

A: Utilizing this furnace provides consistent and uniform heat treatment, increased thermal efficiency, programmable process control, and improved component longevity. It helps prevent structural failures and extends the service life of welded or fabricated metal products.Q: Which heating element materials are used and how do they affect performance?

A: The furnace offers Kanthal and Silicon Carbide heating elements. Kanthal provides durability and cost-effectiveness, while Silicon Carbide enables higher temperature capabilities and better heat transfer, resulting in superior process control and efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Furnace Category

Lead Melting Furnace

Price 50000-200000 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : High thermal efficiency, robust construction, easy operation, safety controls

Application : Battery manufacturing, lead smelting, recycling units

Condition : New

Voltage : 220V / 380V / 440V

Copper Annealing Furnace

Price 50000-200000 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : High efficiency, Energy saving, Uniform heating, PLC control

Application : Heat treatment of copper wires, rods, strips

Condition : New

Voltage : 380V/415V

Copper Vacuum Annealing Furnace

Price 50000-200000 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : fireresistant and heat preserving

Application : the bright annealing of copper

Condition : New

Voltage : 220380 Volt (v)

Metal Melting Furnace

Price 50000-200000 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : fireresistant and heat preserving

Application : Industrial

Condition : New

Voltage : 220380 Volt (v)

|

JAYESH ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry