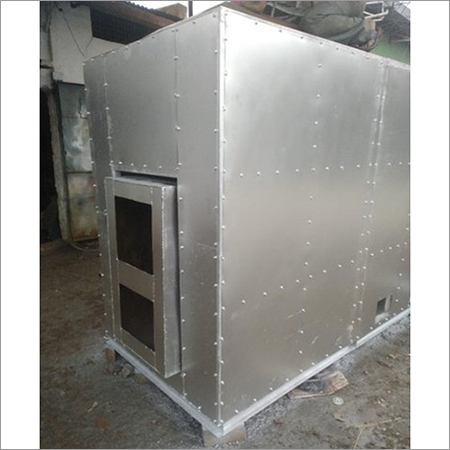

Copper Annealing Furnace

Price 50000-200000 INR/ Unit

Copper Annealing Furnace Specification

- Rating

- Industrial Grade

- Feature

- High efficiency, Energy saving, Uniform heating, PLC control

- Condition

- New

- Type

- Continuous Annealing Furnace

- Usage

- Copper Wire Annealing

- Power

- 20 kW to 100 kW (depending on model)

- Voltage

- 380V/415V

- Size

- Customizable as per requirement

- Dimensions

- Varies with model (Typical: 15m x 2.5m x 2.8m)

- Weight

- Approx. 8 Tons

- Application

- Heat treatment of copper wires, rods, strips

- Fuel Type

- Electric/Gas/Oil

- Capacity

- 500 kg/hr to 2000 kg/hr

- Chamber Design

- Single / Multi-Zone

- Insulation

- High Density Ceramic Fiber

- Cooling System

- Integrated Water Cooling / Air Cooling

- Door Type

- Motorized / Manual

- Heat Source

- Electric Heaters / Gas Burners

- Installation

- On-site Services Provided

- Loading Type

- Batch / Continuous

- Safety Features

- Overheat Protection, Emergency Stop

- Compliance

- CE / ISO Standards

- Service Support

- 24/7 Technical Support

- Automation Level

- Fully Automatic / Semi-Automatic

- Control System

- PLC Based / Digital Controller

- Temperature Range

- Up to 800°C

- Surface Finish

- Powder Coated / Painted

- Material of Construction

- Stainless Steel / Mild Steel

- Atmosphere Control

- Nitrogen / Hydrogen / Inert Gas Environment

Copper Annealing Furnace Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 2-3 Week

About Copper Annealing Furnace

Versatile Control & Automation

This furnace features highly configurable automation levels, with options for fully automatic or semi-automatic operation. Advanced PLC-based or digital controllers facilitate precise temperature regulation and process monitoring, ensuring consistent annealing results for copper materials.

Energy-Efficient & Uniform Heating

With high-density ceramic fiber insulation, the furnace guarantees excellent heat retention and uniform heating throughout the chamber. The use of electric heaters or gas burners not only enhances energy efficiency, but also provides flexibility in energy sourcing for diverse industrial needs.

Robust Construction & Customization

Built with Stainless Steel or Mild Steel and powder-coated/painted finishes, the furnace withstands industrial wear and tear. Its modular design supports single or multi-zone chambers, adaptable loading types, and customizable sizing to cater to specific production requirements.

FAQs of Copper Annealing Furnace:

Q: How does the Copper Annealing Furnace ensure uniform heating during the annealing process?

A: The furnace uses high-density ceramic fiber insulation and is designed with single or multi-zone chambers, which enable even temperature distribution throughout the workspace. This, combined with integrated control systems, ensures that all copper wires or rods receive consistent treatment.Q: What control options are available for operating the furnace?

A: Operators can choose between PLC-based (Programmable Logic Controller) or digital controllers. These allow for precise setting and automation of temperature, timing, and atmosphere parameters, tailored to either fully automatic or semi-automatic operation modes.Q: When should you use an inert or reducing atmosphere like Nitrogen or Hydrogen in the annealing process?

A: Inert or reducing gases, such as Nitrogen or Hydrogen, are used when the copper must be protected from oxidation or contamination during annealing. This is critical for ensuring surface finish quality and metal integrity, especially in high-purity or high-conductivity applications.Q: Where can the Copper Annealing Furnace be installed and by whom?

A: The furnace is designed for installation in industrial manufacturing facilities. On-site services for installation and commissioning are provided by the supplier or manufacturer, ensuring a seamless setup process.Q: What are the benefits of using integrated water or air cooling systems?

A: Integrated cooling systems allow for controlled reduction of copper temperature after the annealing process. This improves throughput, stabilizes product quality, and minimizes post-process handling, making it suitable for either batch or continuous production lines.Q: How does the furnace achieve energy savings and high efficiency?

A: The system combines energy-efficient heating sources (electric, gas, oil) with advanced insulation and process control. This reduces heat losses, optimizes energy use for each batch, and supports sustainable, cost-effective operation.Q: What technical support and compliance standards are offered?

A: Manufacturers provide 24/7 technical support and ensure that every furnace meets CE and ISO standards. This guarantees both operational reliability and regulatory compliance, instilling confidence for industrial users worldwide.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Furnace Category

Stress Relieving Furnace

Price 50000-200000 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Feature : Uniform Temperature Distribution, High Thermal Efficiency, Programmable Temperature Controller

Voltage : 380440 V

Application : Stress Relieving Heat Treatment processes for fabricated and welded structures

Lead Melting Furnace

Price 50000-200000 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Feature : High thermal efficiency, robust construction, easy operation, safety controls

Voltage : 220V / 380V / 440V

Application : Battery manufacturing, lead smelting, recycling units

Electric Furnance

Price 50000-200000 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Feature : fireresistant and heat preserving

Voltage : 220380 Volt (v)

Application : Industrial

Annealing And Electric Furnace

Price 50000-200000 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Feature : fireresistant and heat preserving

Voltage : 220380 Volt (v)

|

JAYESH ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry