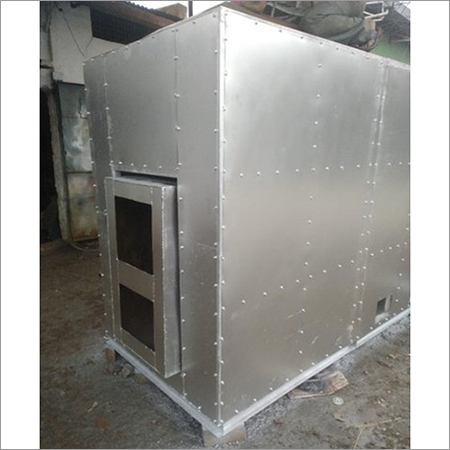

Lead Melting Furnace

Price 50000-200000 INR/ Unit

Lead Melting Furnace Specification

- Rating

- Industrial Grade

- Feature

- High thermal efficiency, robust construction, easy operation, safety controls

- Condition

- New

- Type

- Lead Melting Furnace

- Usage

- Lead ingot melting, recycling, re-casting

- Power

- 5 kw to 50 kw (depending on model)

- Voltage

- 220V / 380V / 440V

- Size

- Customizable (standard sizes available upon request)

- Dimensions

- As per design (varies by capacity and model)

- Weight

- Varies by model (approx. 250 kg to 1600 kg)

- Application

- Battery manufacturing, lead smelting, recycling units

- Fuel Type

- Electric / Oil Fired

- Capacity

- 50 kg to 2000 kg per batch

Lead Melting Furnace Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 2-3 Week

About Lead Melting Furnace

Robust Construction & Superior Efficiency

Engineered with mild steel or stainless steel and reinforced with refractory lining, this lead melting furnace ensures long-lasting durability and outstanding thermal performance. Its heat-resistant coating and ceramic or firebrick insulation maximize operational safety and thermal efficiency, minimizing heat loss during intensive cycles. The system handles capacities from 50 kg up to 2000 kg per batch, making it suitable for small workshops and large recycling units.

Intelligent Controls & Flexible Design

The furnace features an advanced digital temperature controller for accurate monitoring and regulation of the melting process up to 1100C. It is available in manual or semi-automatic configurations, and can be customized in fixed or portable forms depending on workspace requirements. Multiple voltage and power options (from 5 kW to 50 kW) allow seamless integration into various industrial electrical systems.

Optimal Safety and Environmental Protection

Safety is paramount, with built-in over-temperature protection, insulated body, and robust exhaust or chimney systems to extract fumes safely. The natural or water-cooled options, alongside insulated bodywork, ensure operator safety. The eco-friendly extraction and containment measures support compliance with industrial safety and environmental guidelines.

FAQ's of Lead Melting Furnace:

Q: How does the Lead Melting Furnace achieve precise temperature control during operation?

A: The Lead Melting Furnace is equipped with a digital temperature controller, allowing operators to set and monitor temperatures with high accuracy-up to 1100C. This ensures consistent and efficient melting processes while safeguarding against overheating through integrated safety controls.Q: What materials are used in constructing the furnace, and how does this benefit users?

A: Constructed from durable mild steel or stainless steel and lined with high-quality refractory materials like ceramic or fire bricks, the furnace offers enhanced heat retention, structural integrity, and long-term durability, making it well-suited for intensive industrial usage.Q: When is it recommended to use the water-cooled option instead of natural cooling?

A: The water-cooled option is advisable for higher-capacity models, prolonged operations, or when ambient temperatures are elevated, as it enhances thermal management and maintains the longevity of internal components by efficiently dissipating excess heat.Q: Where can this lead melting furnace be installed and operated?

A: This furnace is suitable for installation in industrial environments such as battery manufacturing plants, recycling units, and lead smelting facilities across India. Its fixed or portable design options allow adaptation to factory layouts or mobile operations as required.Q: What process does the furnace follow for safe lead melting and recycling?

A: Lead ingots are loaded into the refractory-lined chamber, and the temperature is set via the digital controller. Heating is achieved using high-quality NiCr resistance wires or oil burners, depending on the model. Fume extraction is managed by the exhaust chimney, and safety features like over-temperature protection ensure secure operation throughout the melting process.Q: How can users benefit from the furnace's customizable features?

A: The furnace offers adjustable batch sizes (50 kg to 2000 kg), choice of heating element, power, and voltage configuration, and either fixed or portable designs. These customizable options allow end-users to optimize the furnace for their specific production volume requirements and site constraints.Q: What are the key usage and operational advantages of this furnace in industrial settings?

A: Designed for lead melting, recycling, and recasting, the furnace delivers high thermal efficiency, rapid melting times (60 to 120 minutes per batch), user-friendly controls, robust safety mechanisms, and minimal maintenance, making it a reliable, cost-effective solution for manufacturers, recyclers, and processors.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Furnace Category

Copper Vacuum Annealing Furnace

Price 50000-200000 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : fireresistant and heat preserving

Condition : New

Voltage : 220380 Volt (v)

Application : the bright annealing of copper

Metal Melting Furnace

Price 50000-200000 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : fireresistant and heat preserving

Condition : New

Voltage : 220380 Volt (v)

Application : Industrial

Annealing And Electric Furnace

Price 50000-200000 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : fireresistant and heat preserving

Condition : New

Voltage : 220380 Volt (v)

Wood Fire Hot Air Furnace

Price 50000-200000 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : fireresistant and heat preserving

Condition : New

Application : Industrial

|

JAYESH ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry