Most Popular Products

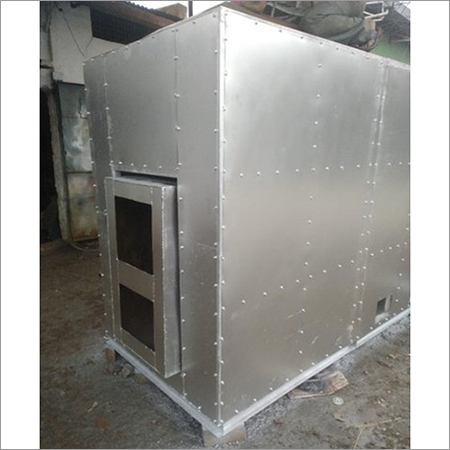

Industrial Powder Coating Oven

Price 50000-200000 INR/ Unit

MOQ : 1 Unit

Industrial Powder Coating Oven Specification

- Control Mode

- Digital PID Controller

- Condition

- New

- Heating Capacity

- Up to 300C

- Accuracy

- 2C

- Heating Method

- Hot Air Circulation / Electrical Heating

- Power Source

- Electric

- Type

- Batch Type - Walk In

- Model

- Industrial Powder Coating Oven

- Internal Size

- 1200 x 1200 x 1800 mm

- External Size

- Customizable as per client requirement

- Volume

- 2.5 m

- Air Flow

- Forced Air / Uniform Distribution

- Temperature Range

- 50C to 300C

- Material

- Mild Steel (MS) with Heat Resistant Paint

- Dimension (L*W*H)

- Customizable

- Power

- 12 kW

- Voltage

- 380 V / 415 V

- Surface Finish

- Powder Coated

Industrial Powder Coating Oven Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Week

- Delivery Time

- 2-3 Week

About Industrial Powder Coating Oven

Industrial Powder Coating Oven is extensively used in ceramics, paints, plastic, paper and many others. It is manufactured by our skilled professionals using modern technology and top notch quality components in line with industry standards. Rendering smooth operation, this Industrial Powder Coating Oven is available in different designs and sizes to meet various demands of our clients.

Precision Digital Control & Safety

Benefit from advanced digital PID control with over-temperature and overcurrent protection, ensuring accurate curing and enhanced operator safety. The oven's modern control system maintains temperature within 2C, vital for high-quality and consistent coatings, while safety features safeguard both personnel and materials during prolonged operation.

Superior Insulation & Construction

Built with high-density mineral wool insulation (100 mm) and double-walled insulated doors, the oven minimizes heat loss, reduces energy consumption, and keeps exterior surfaces cool to the touch. The robust mild steel construction is finished with heat-resistant powder-coated paint for durability and long service life in demanding industrial settings.

Customizable & Versatile Design

Accommodate components of varying sizes, thanks to customizable internal and external dimensions. Optional castor wheels provide mobility within the factory, and custom colors ensure your oven matches facility aesthetics. This oven is suitable for batch-type, walk-in use, making it ideal for diverse industrial component finishing needs.

FAQ's of Industrial Powder Coating Oven:

Q: How does the industrial powder coating oven ensure uniform temperature and airflow?

A: The oven utilizes forced hot air circulation via an industrial-grade blower, ensuring uniform heat distribution throughout the chamber. Combined with high-efficiency tubular heaters and precise digital PID control, this guarantees consistent curing finishes on metal, aluminum, and automobile parts.Q: What safety features are included in the control and construction of this oven?

A: Safety is prioritized with overcurrent and overheat protection in the digital control panel, double-walled insulated doors with sealing gaskets, and high-density mineral wool insulation. These features protect both operators and components during operation.Q: When and where is this oven best installed?

A: The oven is designed for indoor installation, typically on a factory floor. It is ideal for environments requiring reliable powder coating, paint baking, or component curing, and comes with optional castor wheels for easy mobility within industrial setups.Q: What is the process for using the powder coating oven for industrial components?

A: After pre-treatment and powder application, components are loaded into the oven's walk-in chamber. The operator sets the required temperature and timer on the digital PID controller. The oven circulates hot air for even curing before parts are safely removed for cooling and finishing.Q: Which applications and industries benefit most from this powder coating oven?

A: Manufacturers, fabricators, exporters, suppliers, and retailers in sectors such as automotive, metalworking, and general industrial manufacturing benefit from the oven's robust construction, precise controls, and customization options.Q: How customizable is the oven to match specific client requirements?

A: Both internal and external dimensions can be tailored to suit different batch sizes and factory layouts. Additional options such as custom colors and mobility (castor wheels) are also available to meet unique operational needs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

JAYESH ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry